Business

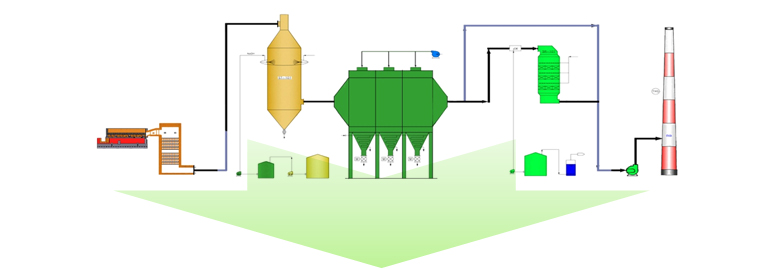

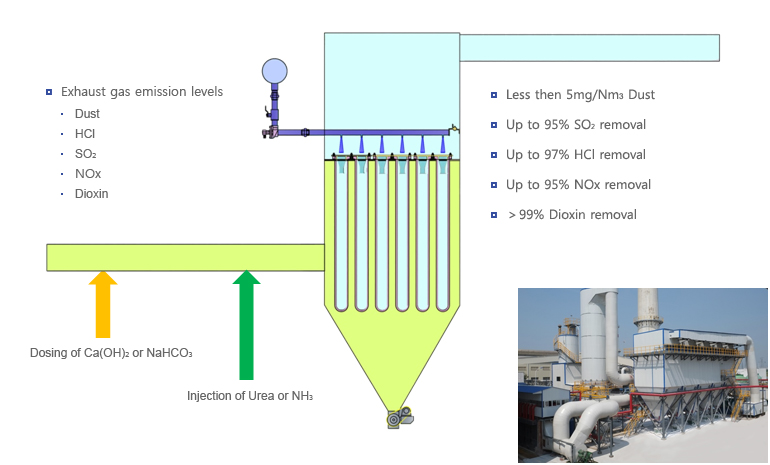

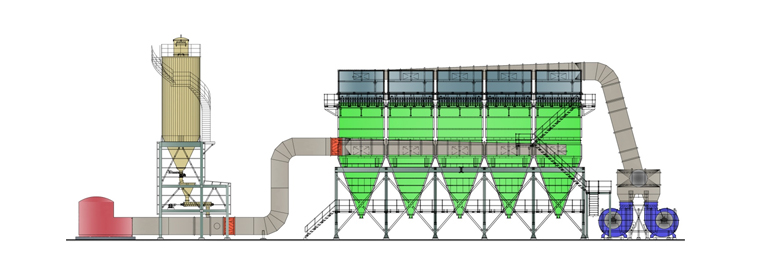

Dry Reactor Type Gas Treatment System

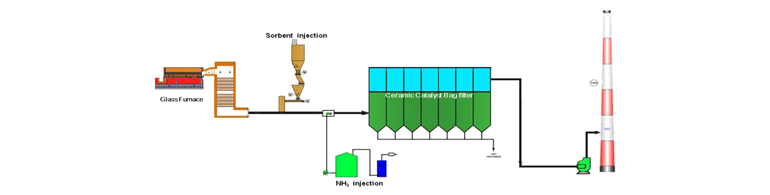

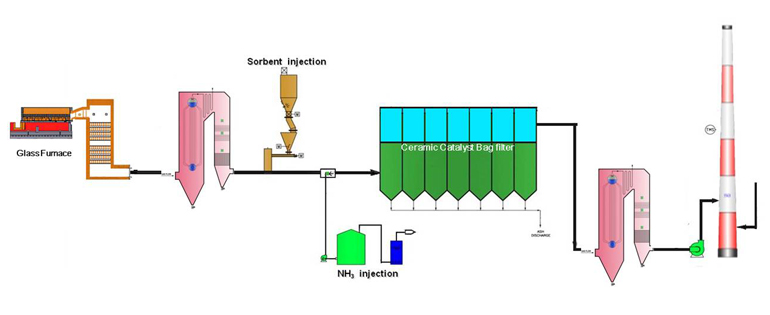

Comparison with conventional process

- SDR + ESP +SCR process

- Ceramic Catalyst Bag filter process

- SDR + Bag Filter + GGH + Re-heater + SCR process

Ceramic Catalyst Bag filter process’s characteristics

- Operation temperature is high.

- SCR : 350 ℃ ± 20℃ ( Nor 350℃ )

- Ceramic Bag : 200℃ ~ 900℃

- In Ceramic Catalyst Bag filter, temperature drop is low as 30℃. So, before and after process, heat recovery system like waste heat boiler can be installed.

- Because gas reheating like SCR is not necessary, cost for energy loss can be minimized.

- High efficiency of treating gaseous pollutant

- High efficiency of dust collection ( Outlet concentration is about 5mg/Nm3 )

- Efficiency of treating Dioxin is high. By operating at high temperature, additional Dioxin doesn’t occur.

- Electricity cost and chemical cost are less. So, operation cost is cheaper than conventional process.

- Simple process. Easy operation and management. ( same with general operation method of bag filter )

- Compact space for installation.

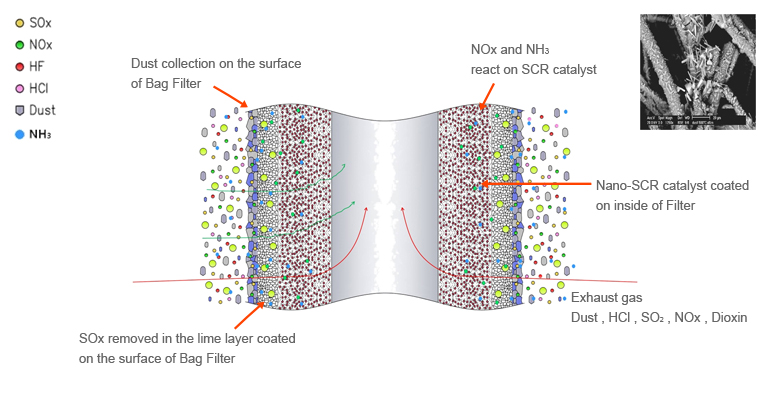

Mechanism of Ceramic Catalyst Bag filter

- Dust contained in exhaust gas are removed on surface of Bag Filter.

- Pre-coat on surface of bag filter with Lime or Sodium Bicarbonate to remove SOx.

- By passing reducing agent like NH3 or Urea through SCR catalyst layer (20mm thickness) on bag filter fiber, NOx is decomposed to N2 and H20 and then removed.

- This is a well blended technology of ceramic bag for high temperature and SCR catalyst and achieves best efficiency of de-SOx and de-NOx at 350 ℃

Application fields of Ceramic Catalyst Bag filter process

- Glass furnace

- Incinerator

- Coal-firing boiler

- Steel manufacture

- Cement

- Power Plant

Tel : 02-2672-5565 E-mail : haecheon5301@gmail.comFax : 02-2675-1128

Address : Munjeong Hyundai Knowledge Industry Center B-Dong 609, 11 Beobwon-ro 11-gil, Songpa-gu, Seoul, Republic of Korea, 05836Factory Address : 512, Nojang-ri, Jeondong-myeon, Sejong, Korea

Address : Munjeong Hyundai Knowledge Industry Center B-Dong 609, 11 Beobwon-ro 11-gil, Songpa-gu, Seoul, Republic of Korea, 05836Factory Address : 512, Nojang-ri, Jeondong-myeon, Sejong, Korea

COPYRIGHT(c) 2015 Haecheon Co., Ltd. ALL RIGHTS RESERVED