Business

Incinerator exhaust gas treatment system

Incinerator exhaust gas treatment system

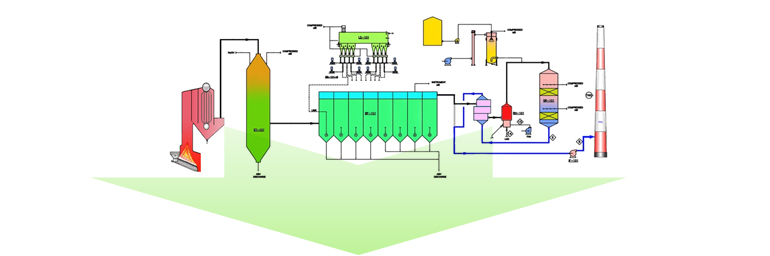

Conventional incinerator exhaust gas treatment process is SDR + Bag Filter + SCR process.

We design and apply new process to improve problems of conventional process and for easy management.

- SDR + Bag Filter + GGH + Re-heater + SCR process

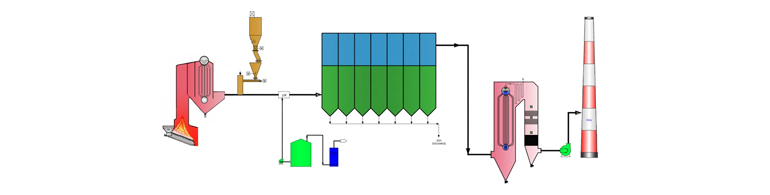

- Ceramic Catalyst Bag filter process

Ceramic Catalyst Bag filter process properties

- As one process, it can treat SOx, HCl, HF, NOx, Dioxin, gaseous pollutant

and dust simultaneously. - Because operation temperature is high, additional dioxin doesn’t occur.

- Applying SCR 350 ℃ ± 20℃ ( Nor 350℃ )

- Ceramic Bag : 200℃ ~ 900℃

- Temperature drop of Ceramic Catalyst Bag filter is low, about 30℃.

- Gas re-heating is not necessary for SCR operation.

So, cost for energy loss can be minimized. - Treating gaseous pollutant is available with high efficiency ( more than 90% )

- High efficiency of dust collection ( outlet concentration : about 5mg/Nm3 )

- Energy cost like gas re-heating is not necessary.

So, operation cost is cheaper than conventional process. - Simple process. Easy operation and management

( same of general bag filter operation method ) - Compact space for installation.

Tel : 02-2672-5565 E-mail : haecheon5301@gmail.comFax : 02-2675-1128

Address : Munjeong Hyundai Knowledge Industry Center B-Dong 609, 11 Beobwon-ro 11-gil, Songpa-gu, Seoul, Republic of Korea, 05836Factory Address : 512, Nojang-ri, Jeondong-myeon, Sejong, Korea

Address : Munjeong Hyundai Knowledge Industry Center B-Dong 609, 11 Beobwon-ro 11-gil, Songpa-gu, Seoul, Republic of Korea, 05836Factory Address : 512, Nojang-ri, Jeondong-myeon, Sejong, Korea

COPYRIGHT(c) 2015 Haecheon Co., Ltd. ALL RIGHTS RESERVED